Service

We offer professional solutions to adapt to market changes in rubber and plastic machinery, ensuring optimal machinery performance and product yield.

Research and Development

Cooperate with you on product development

-

- Where can we reduce energy usage or material consumption?

- How can we further enhance product strength or recyclability?

- How can we assist you with product development?

Quality Management

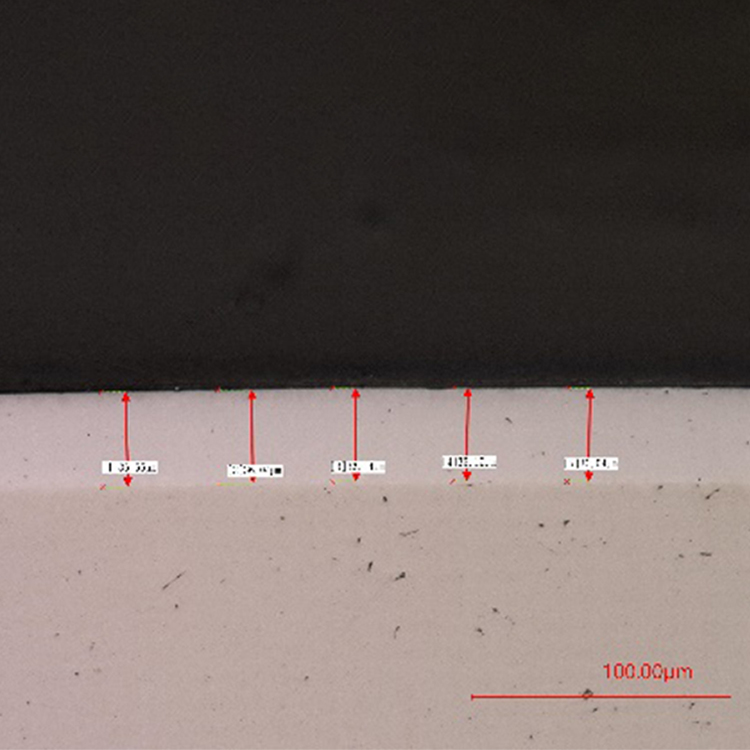

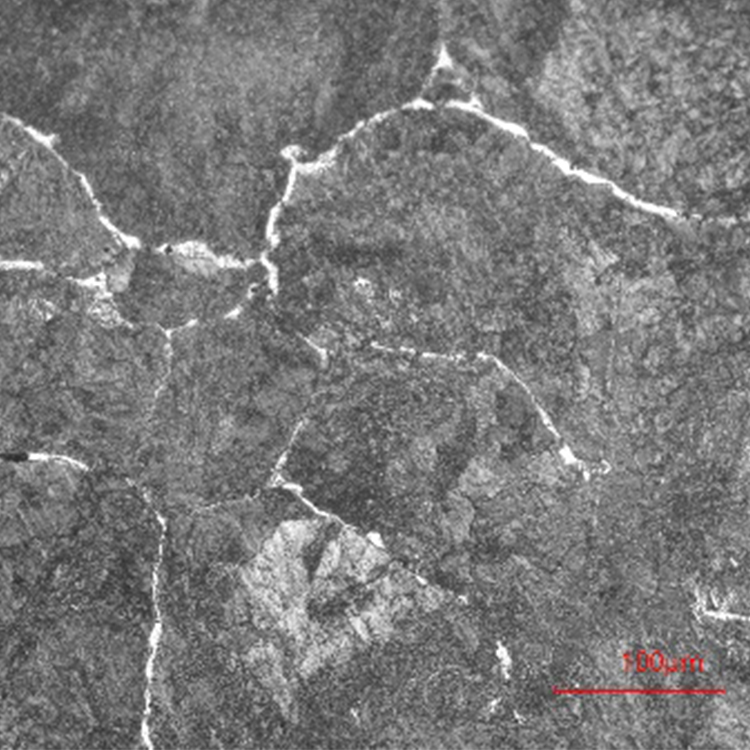

Professional inspection instruments are used to measure the structure, metallography, and hardness of steel.

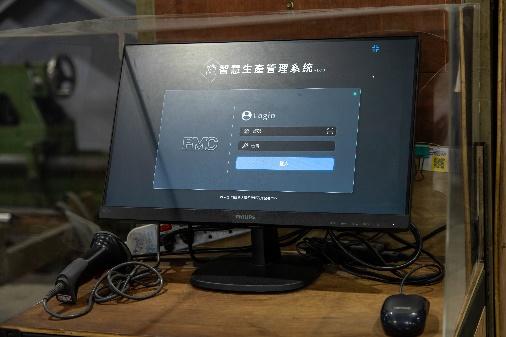

Digital quality measurement is used to meet the highest quality requirements.

- Surface Rougthness Tester

- Rockwell hardness indicator

- Three point internal micrometer

- Bore gauge

- Digimatic External Micrometer

- Caliper

- Thickness gauge

- Metal Cutting Machine Tools

- Mounting Press Machines

- Metallographic grinder

- Metallographic microscope

- Micro Vickers

Customer Achievements

◆

Minimal Challenge

Accepted the customer's request to manufacture double alloy extruded tube sets specifically for wires, and successfully met the customer's requirements.

| Challenge the Limits, Smallest Ni Base Bi-Metallic Extrusion Barrel and Screw Series |

|

| Screw Processing Material |

Ni Base |

| Aperture | Ø12mm |

| Length |

300mm |

| Plastic Raw Materials AdaptiveTeflon | Teflon |

◆

Great challenge

Production extruder material tube hole diameter 300mm,

◆ Acceptance based on product quality

Strict quality requirements, taking the wire and cable industry as an example, assist in the design of screws and tubes to achieve the highest quality of cables.