Injection Molding Series

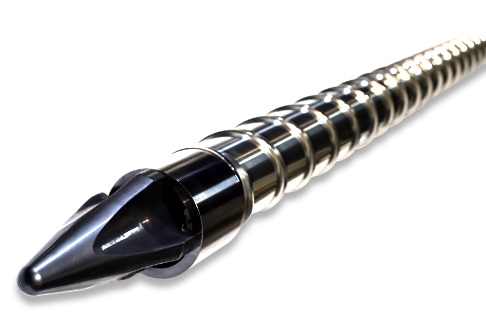

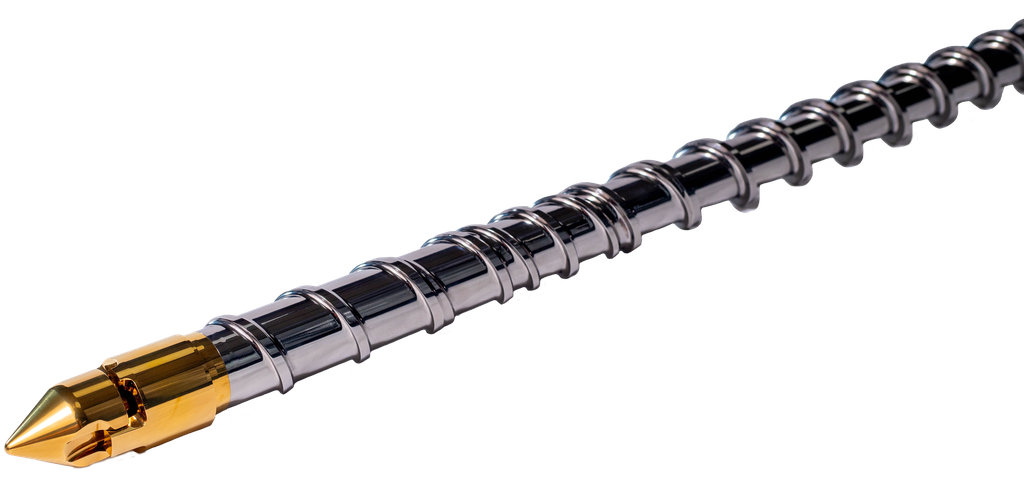

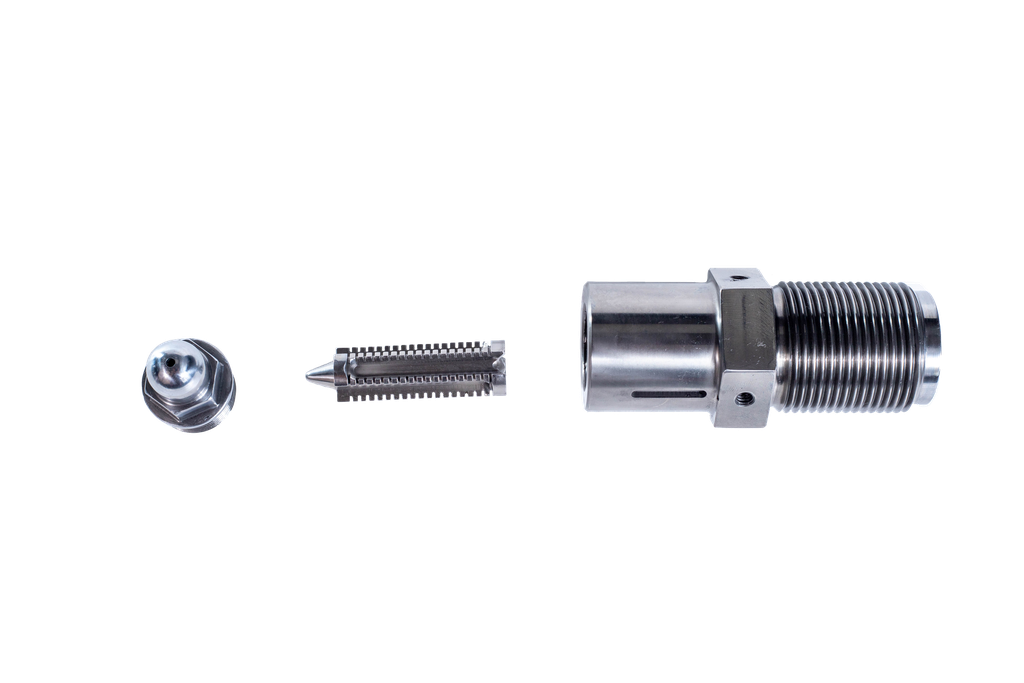

The screws and barrels are the core component of the injection molding machine. In response to the use of different plastic and additives, Top Screw provides different level of barrel and different types of screws.

Specification

▼Barrel Processing Range

| Nitrided Barrel |

Internal Diameter: Ø12~Ø280mm, Length: 7000mm |

| Bi-Metallic Barrel |

Internal Diameter; Ø12~Ø280mm, Length: 6000mm |

▼ Barrel Processing Material

| Grade |

Materials |

Application |

| Nitrided Barrel |

SACM645、ACM2 |

Resin with Glass-fibre < 5% |

| Bi-Metallic Barrel | HRC 50-55 | Resin with Glass-fibre 10-20% |

| Bi-Metallic Barrel | HRC 55-60 | Resin with Glass-fibre 20-30% |

| Bi-Metallic Barrel | HRC 60-65 | Resin with Glass-fibre 30-50% |

▼ Screw Processing Range

| Outer Diameter: Ø12~Ø300mm, Length : 7000mm |

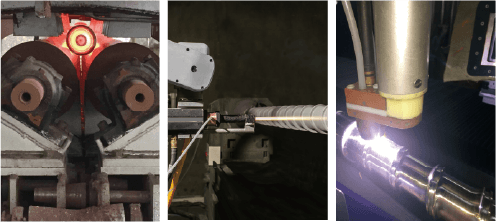

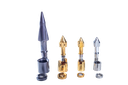

▼ Screw Processing Methods

Due to the different raw materials used by customers, the design of our screw has faster screw feed back time and better temperature control.

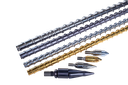

| Eletro Plating | Vacuum | Nitrided |

| TiAl PVD Coating | PTA Welding Screw / HVOF Spray Coating Screw | PTA Welding Screw / HVOP Spray Coating Screw |

▼ Screw Processing Material

| SACM440(1.7225/4140) | SACM645(1.8509/7140) | SKD-61(1.2344/H13) |

| SKD-11(1.2379/D2) | 1.8550(38CrAlNi7) | powder alloy steel、Powder high speed steel |